Introduction

| “According to Grand View Research, Inc., the global automotive aftermarket industry is expected to reach USD 486.36 billion by 2025 and grow at a CAGR of 3.8% from 2025 to 2030.” |

The Growing Complexity of Auto Parts Fitment Data

The automotive part industry needs more lubrication to smoothly slide for the right amount of digital transformation to simplify the auto part manufacturing, supply chain, repair, and insurance for enhanced customer experience (CX). The industry is on the cusp of a transformation where the growing complexity of auto parts fitment data due to variety, type, volume, spare parts, manufactures, and introduction of EVs need precise parts data management and Product Information Management (PIM) to provide accurate and compatible parts in lesser time.

The fitment data is huge due to various makes, models, and years with detailed parts specifications, compatibility information, OEMs, pricing, and technical documentation for thousands of parts and accessories. And then, the constant churn of innovation to make driving an amazingly pleasurable experience makes it more complex to finalize a list of auto fitment data; the innovative product engineers are adding more parts to the drivetrain, releasing new models, and updating the existing ones. Feels like it’s ready to go into overdrive with time for more complex parts and structure for more comfort.

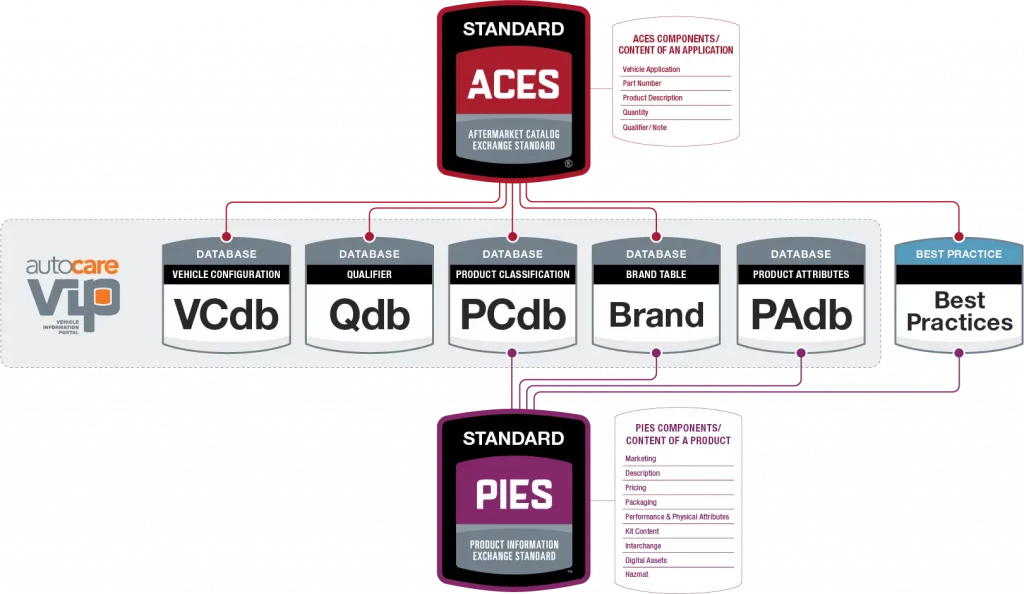

Image Courtesy: Auto Care Association

Why Traditional Fitment Systems Struggle to Keep Up

The traditional means of managing auto parts fitment follows the manual processes to manage fitment data and product information that leads to errors like incorrect part recommendations, mismatched spare parts, lack of standardized approach, and supply chain disruptions due to customer dissatisfaction.

In order to fix this issue, the Auto Care Association established standards like ACES ( Aftermarket Catalog Exchange Standard (ACES®) and PIES (Product Information Exchange Standard (PIES™) to streamline fitment and product information in the automotive parts aftermarket and enable efficient data exchange among industry stakeholders like parts suppliers, service provides, insurance companies, dealers, and other partners.

To a certain extent, both of these standards play a vital role in bringing accuracy and consistency across the sales channels and service network. Following these two ACES and PIES standards help auto parts manufacturers, suppliers, and service networks to efficiently minimize return rates, streamline operations, manage fitment data, and also decrease costs for parts sales channels and suppliers.

Understanding AI-Powered Fitment Engines

The automotive industry has a remarkable history of innovation, adoption, and transformation to bring effectiveness to its product development, operations, and product design. The automotive industry evolves with innovation to thrive and grow with time; however, auto parts fitment operations, aftermarket parts development, distribution, and dealerships still rely on legacy systems, such as manual fitment data management.

In order to transform this legacy system with a new and advanced fitment data management, sales channel, and service network, the use of new-age advanced technologies like Artificial Intelligence (AI), Machine Data Analytics, Learning (ML), AR & VR, and more are highly recommended.

What Are AI-Driven Fitment Engines?

Artificial Intelligence (AI) is a revolutionary technology for fitment data management that efficiently automates and optimizes the automotive parts fitment data. AI-driven fitment data management helps auto parts suppliers and dealers get accurate and consistent product information about vehicle configurations, product catalogs, and spare parts lists for various brands, models, and variants. It efficiently uses generative AI algorithms for data cleansing, analysis, standardization, security, and validation to find parts mismatches, inconsistencies, and potential fitment issues to bring more accuracy and data quality.

AI can use predictive analytics on existing and historical data to find fitment data patterns and predict potential parts and production requirements. We can’t ignore the crucial role of artificial intelligence in search and retrieval with real-time fitment data monitoring to quickly find the latest updated and accurate fitment information, even with ambiguous search terms.

The Role of Machine Learning in Auto Parts Mapping

The application and uses of Machine Learning (ML) technology in the automotive industry enhance the auto parts source-to-target mapping for more accurate and precise information. ML algorithms automate auto parts mapping by enabling continuous learning to identify patterns and predict compatibility between parts and vehicles. Machine Learning uses image recognition and Optical Character Recognition (OCR) technology to search and identify auto parts as well as fitment data mapping to organize and classify data to design a manageable and easy-to-understand auto parts data management system. In the aftermarket auto parts network, the use of ML helps dealers and service providers find and recommend compatible parts based on vehicle models, makers, OEMs, part numbers, and other data.

How AI Enhances ACES & PIES Data Processing

Though, with the introduction of ACES (Aftermarket Catalog Exchange Standard) and PIES (Product Information Exchange Standard), auto parts manufacturers and dealers are able to standardize fitment data and other parts information up to a certain extent, yet the process needs more accuracy, real-time, and faster updates, and more integration for wider availability across the stakeholders. Artificial intelligence (AI) plays a significant role in expanding ACES and PIES databases to enhance efficiency, faster data updates and search capability, and better product information management (PIM). AI algorithms enable automated data processing and analysis to find inconsistencies, mismatched or incomplete entries, and errors in ACES and PIES data to gain more accuracy and reliability.

Benefits of AI in Fitment Data Integration

When we think of Artificial Intelligence for the automotive industry, we always think about experiences like Advanced Driver-Assistance Systems (ADAS, self-driving cars, and more; however, AI has a wider role in automotive operation enhancement. We can say that artificial intelligence (AI) is taking the front seat in changing automotive parts and aftermarket operations. It automates data integration from various sources, enhancing data quality, and enabling faster, more accurate decision-making with meaningful data insights.

Image Courtesy: Carorbis

Automating VIN-Based Fitment Matching for Precision

AI’s growing capability and functionality in auto parts fitment data integration enables automated VIN-based fitment matching to enhance accuracy, faster parts search and availability, and better customer satisfaction. The automotive industry has the Vehicle Identification Number (VIN) as a crucial and essential factor that helps to identify granular details about any vehicle, including manufacturer, make, model, production year, ownership, accidents, recall information, theft, and other information.

This 17-character sequence VIN is essential for car registration, insurance, recall tracking, service, and theft prevention for accurate records and compliance. VINs can be integrated and stored electronically on a cloud or data management system to quickly get accurate information about car parts, maintenance routines, insurance, and service schedules. The headline-grabbing use is when an AI-powered fitment data management system integrates VINs for more accurate details of cars with virtually zero error and inconsistency.

The use of AI and VINs is revolutionary for automotive eCommerce to simplify parts search across various eCommerce technologies. Automotive eCommerce parts businesses and aftermarket suppliers can easily integrate this functionality into their eCommerce stores and get the precise and complete list of VIN-based fitment data using Vehicle Identification Number (VIN). Plus, if we can integrate Optical Character Recognition (OCR) technology into it, then the fitment data will be easier to collect, process, and search for a wider target customer segment that ultimately enhances the operations and service network.

Image Courtesy: Width

Reducing Errors in Year-Make-Model (YMM) Cataloging

We already know that dealing with various parts makers and suppliers is challenging due to the non-standardized, inconsistent, and unorganized nature of product fitment data, and then comes the Year Make Model (YMM) challenge to turn this into a more complex process. Despite ACES and PIES standards, some suppliers provide their own non-standardized data to make fitment data and Product Information Management (PIM) troublesome

Real-Time Adaptation to New Vehicle Models and Market Trends

Artificial intelligence (AI) automates fitment data and Product Information Management (PIM) for product categorization in a single repository to harmonize YMM data from multiple sources. Its AI model creates a defined structured format for product catalog based on various attributes like Year, Make, Model, and Engine (YMM), data part numbers, product descriptions, parts images, and other specifications. It reduces errors due to manual data management and updates, as well as the time taken. Plus, the Generative AI enables real-time adoption to fitment data and spare parts information of new vehicle models with trends analysis and predictions using historical and predictive datasets for optimal production, streamlined supply chain, and enhanced safety measures to ensure a delighted customer experience (CX) at various touchpoints of customer journey.

Implementation Strategies for AI-Powered Fitment

One of the most significant developments AI has brought is the advanced capability to transform the legacy system with a more efficient, accurate, and faster one. Integrating AI-powered fitment engines into automotive eCommerce stores can help suppliers and dealers to enhance their revenue and customer experience.

Integrating AI Fitment Engines with Existing eCommerce Platforms

It seamlessly integrates the VIN-based vehicle fitment data, ACES (Aftermarket Catalog Exchange Standard), and PIES (Product Information Exchange Standard) product catalogs with the existing eCommerce stores to enable automotive part search for various attributes or product codes like VIN, ACES, PIES, and even OEM information. This ultimately empowers car owners and service providers to search and get the right parts without much return and mismatch for enhanced CX and customer satisfaction. Auto parts eCommerce stores can get expert consultation to integrate AI-powered fitment engines into their existing stores and leverage more efficient and accurate auto parts search for right parts suitable for their customer requirements.

Leveraging Predictive Analytics to Optimize Auto Parts Recommendations

Another application of AI in auto parts fitment data management and eCommerce is the use of predictive analytics in auto parts distribution and recommendations. AI-powered automotive parts eCommerce stores can analyze the data, trends, and patterns to predict the spare parts requirements for seamless production, demand generation, supply chain, and distribution. Automotive manufacturing units can also leverage the AI-powered insights of car service schedules and predict structural integrity to optimize auto parts recommendations.

Enhancing B2B and B2C Search with AI-Powered Fitment Assistants

The use of AI in automated fitment data integration tools enables efficient and effective auto parts search, availability, and customer satisfaction for both the B2B and B2C eCommerce businesses. In the interconnected and updated world of AI-powered fitment data management, users can get a standardized and centralized repository of a broader range of parts for different makes, models, manufacturing years, types of vehicles, and OEMs. It simplifies and enhances the search for spare parts, allowing for easy availability, minimal return, and more profitability with revenue. AI helps accelerate the search process and increase accuracy to change how vehicle manufacturers, suppliers, distributors, and service networks work.

Challenges in AI-Driven Fitment Adoption

AI-driven fitment data management adoption simplifies complex data, product updates, and standardized challenges with automated data fitment management for more accurate, precise, and efficient auto parts data management. However, integrating the AI-driver data fitment into the existing system has its own challenges.

Ensuring Data Accuracy with AI-Led Fitment Models

Artificial Intelligence (AI) in automotive parts and aftermarket dealerships uses Generative AI (Gen AI) technology to create product catalogs based on the existing data, product information, and parts images. The AI-led fitment models might not be able to validate the existing fitment datasets that have inconsistency and errors, so there might be data quality concerns for businesses and customers. However, with the growing use of Generative AI, data analytics, and Optical Character Recognition (OCR) technology, AI-driven fitment engines try to rectify the inconsistencies, automate the data-cleaning, and create synthetic data to fill the gaps in existing data.

Addressing Integration Gaps with Legacy Systems

Another challenge for AI-driven fitment data management adoption is the integration with legacy systems because of the technological disparities, data format incompatibilities, decentralized data, and scalability. The AI-driven models are flexible and scalable and easily implement fitment data mapping, data classification, and service layers or APIs to eliminate data inconsistency and fill the gaps between legacy systems and AI-led systems.

Managing Costs and Scalability for AI-Driven Fitment Solutions

Automotive manufacturing can also leverage AI-driven data fitment solutions in an affordable way without spending huge sums on this integration. Auto parts dealers, especially the aftermarket auto part suppliers, are sensitive to the cost incurred by transforming from legacy to AI-driven systems. AI-driven data fitment solutions are scalable and cost-effective as they save expenses on manual fitment data management and spare parts return.

Automotive part fitment data management using AI to transform the part search, product availability, and service network for better efficiency, scalability, and customer satisfaction. The use of AI-driven fitment data management simplifies car part search without the use of multiple filters. AI-led data fitment engines can work for ambiguous searches to get compatible parts.

Live Use Cases

Let’s say you need brake pads for your Mercedes-AMG GT 63 S E coupe car. You can use the search “brake pads for 2024 Mercedes-AMG GT 63 S E coupe” and quickly get the exact match or a filtered list of compatible spare parts to find the suitable one for your car. If you have the VIN number of your car, then you can directly use it in the search AI algorithm-powered data fitment platform and reach the exact match in no time.

AI-driven parts fitment data management enables automotive parts manufacturers to streamline production and distribution to various stakeholders like dealers, suppliers, aftermarket dealers, and service providers. It helps the transition of a legacy system into a digital parts catalog to instantly get parts with chassis number, VIN number, makers and model with year, and more to locate precise parts with the network exactly. It also helps identify spare parts shortages at the showroom level, generate the requirement with the supplier and manufacturer, and streamline production and distribution. It also uses the predictive AI model to forecast the demand, which helps to minimize the lack of availability or shortages.

Conclusion

The Future of AI in Auto Parts Fitment

Artificial Intelligence (AI) opens up new doors of opportunities for the automotive industry to enhance operational efficiency and customer experience (CX). AI with Machine Learning (ML), Data Analytics, Optical Character Recognition (OCR), and other advanced technologies are driving the future of the automotive industry and its multiple facets to facilitate efficiency and experience. Automotive parts, spare parts, and aftermarket parts are also transforming with the introduction of AI to achieve excellence in operations with efficiency, flexibility, and scalability.

Before AI, the use of legacy systems made it difficult to find the exact match, and even the lack of an integrated system resulted in silos among different stakeholders. Later on, the Auto Care Association brought ACES and PIES to streamline fitment and product information, and then Vehicle Identification Number (VIN) also helped to facilitate it. After the introduction of AI-driven fitment data management, it turned into a more organized, standardized, and streamlined spare parts management system. AI in auto parts fitment is revolutionary in addressing the challenges of unstructured, inconsistent, and unorganized fitment data management.

How Businesses Can Leverage AI for a Competitive Edge

In the future, AI-powered parts fitment data management can be channelized and organized by automotive parts manufacturers, OEMs, aftermarkets, and Genuine Parts suppliers with the service network to streamline the processes and customer experience (CX). Auto parts suppliers, aftermarket dealers, and part manufacturers can leverage Artificial Intelligence (AI) to redefine the operational efficiency of their service network and supply chain. They have endless opportunities to transform experiences, achieve efficiency, and streamline processes with the use of technologies like Artificial Intelligence (AI), Machine Learning (AI), data analysis, and more.

Fuelled by a relentless drive for digital innovation, Naresh Sambhawani is at the forefront of crafting transformative experiences within the dynamic realm of digital agencies. With a knack for pushing boundaries and leveraging emerging technologies, he specializes in creating captivating brand narratives that resonate deeply with audiences.

Recommended Reading:

Advanced Tech Revolutionizing Automotive Aftermarket Industry – Use Cases & Insights

8 April, 2025 Think about the last time you needed an auto part. Did you visit a brick-and-mortar store, or did you pull out your phone and search online? Chances are, it was the latter. The automotive aftermarket industry is shifting gears, and technology is the driving force behind this transformation.

Subscribe with Us!

Never miss any post, stay tuned!

Trusted by leading brands